We likethink of Johannutenberg as inventor of the printing press and movable type in 1450. Yet, the first movable type got invented in China around 1040 by Bi Sheng. The types were made from porcelain material. Later wooden movable types were developed by Wang Zhen around 1297. Koreans evolved the movable type technology further. In 1234 the first books known to have been printed using metallic types was published in Korea. It happened during the Goryeo Dynasty.

So, why are we giving Gutenberg all the credit for inventing printing? Because Gutenberg served the same role for printing as James Watt did for the steam engine. Neither of the men were the original inventors of the concept, but they made improvements so radical that they made the technology transformational.

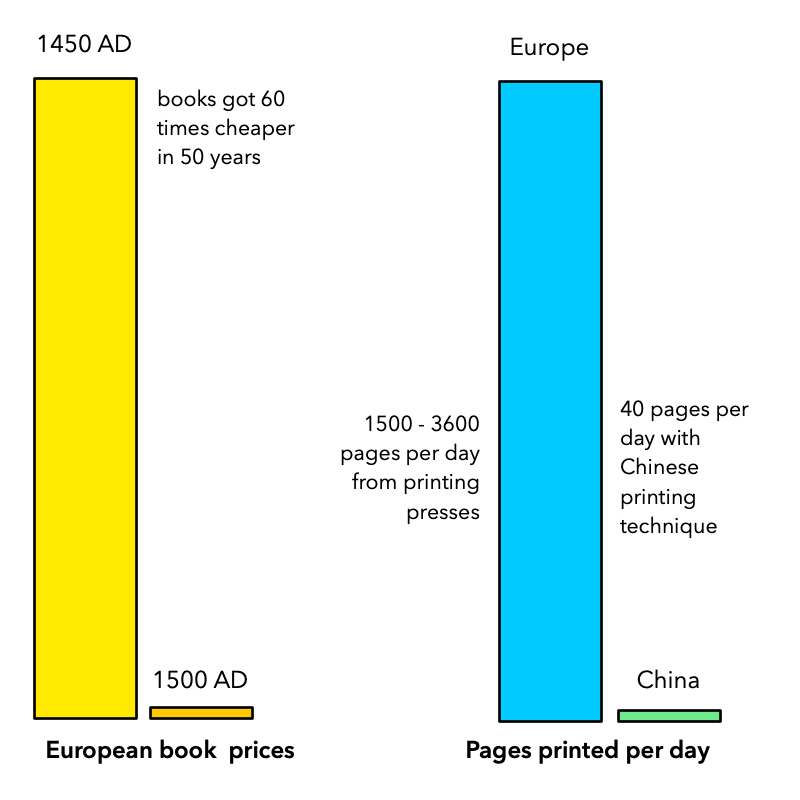

Gutenberg made a mechanical machine, a printing press, which allowed printers to greatly speed up the printing process. Asian printing in contrast involved rubbing paper into types covered in ink. It was not done using a machine, and it was not done using mass-produced metal types. The difference was profound. Around 1600 European printing presses could output 1500 to 3600 pages per day. Chinese printing technique in contrast could only do about 40 pages per day.

The printing press led to a sharp drop in book prices. From the invention of the printing press to 1500, books got about 60 times cheaper. By 1600 books had gotten 300 to a 1000 times cheaper. This price reduction made it possible to spread scientific knowledge cheaply all over Europe. With the lower price came a sharp increase in demand for scientific and academic study.

The printing press also allowed Europeans to catchup with China in literacy. Why were Europeans far behind the Chinese in literacy? A key reason was the lack of a cheap material to write on. Europeans used parchment and vellum, which are both made from animal skins, which make them excessively expensive compared to paper. Although you should keep in mind that the cheap paper we use today, based on wood pulp, wasn't invented until 1844. Thus, when I discuss paper in this story, I am talking about paper made from textiles.

Paper didn't arrive in Europe until the 11th century in the Islamic parts of the Iberian Peninsula (Portugal and Spain). Meanwhile, the Chinese had paper at least since the Han dynasty (25–220 AD).

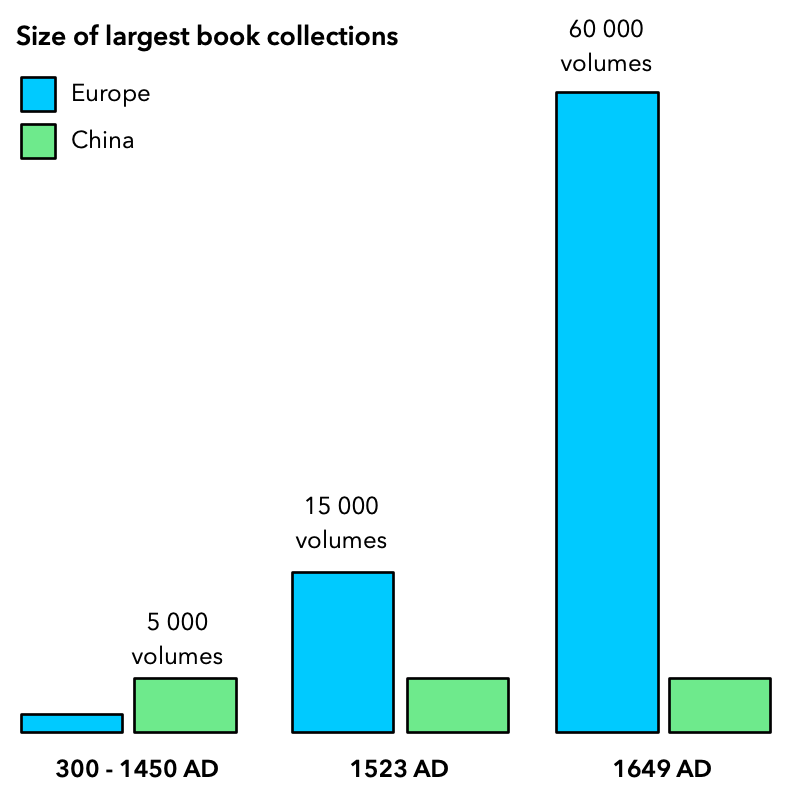

Lacking paper caused Europe to fall far behind China in terms of literacy and published works. From the 4th to the start of the 16th century, the largest Chinese library collections were 3-4 times larger than the largest library collections in Europe.

What is remarkable is that we don't have evidence of paper-making in Germany until 1390. Thus, from the arrival of paper in Germany, it only takes 50 years before Johannes Gutenberg begins working on his printing press in 1440. Ten years later, in 1450, he has perfected the printing press enough to use it for commercial operations.

Thus, from the 15th century European intellectual life became supercharged and a staggering transformation takes place. For instance, the Venetian Domenico Grimani's collection numbered 15,000 volumes by the time of his death in 1523. That was 3 times larger than the largest Chinese book collections. After 1600, European collections completely overtook those in China. The Bibliotheca Augusta numbered 60,000 volumes in 1649 and surged to 120,000 in 1666.

We can agree that the transformation was profound, but the question is: Why was European printing superior to Asian printing? Was it only because of the printing press? And why couldn't the Chinese or Koreans invent a printing press?

It took Germany only 50 years from paper production starting until development of a printing press began. China, in contrast, had a head start of over a thousand years.

Answering this question is actually quite complex because it involves mechanical knowledge, metallurgy, mills and writing systems. I have read numerous articles on this topic, but I started to notice that everyone leaves out some different essential part of the story. Here I am trying to include all the factors involved.

To fully appreciate the next section, I advice you to read my article describing printing terminology and technique.

The advantages of Western printing derives from several innovations by Gutenberg:

-

Using a machine, the printing press, to speed up the printing process

-

A hand mould for creating lead types quickly

-

Using a lead, tin, and antimony alloy for types

-

Oil-based ink rather than traditional water based ink

Imprinting ink on a sheet of paper was a manual and careful process with the Asian movable type system. The printer would rub the paper into the typeset page repeatedly. Gutenberg in contrast used a screw press to transfer ink from the metal types to the paper in one single action. That made printing a page significantly faster.

The printing press also had several features to help align the paper correctly, reducing the chance of human error.

China used carved wood based characters for a long time. Even as late as 1733 we can find major works printed using wood carved characters. The reusable metal matrix pioneered by Gutenberg allowed a single experienced worker to produce 4,000 to 5,000 individual types a day. With wood carving, no more than 70 types could be made per day.

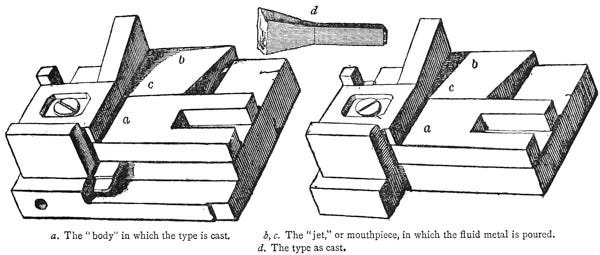

What made it so fast to make types was a simple hand mould similar to the one seen below, where a matrix could be slotted in. The two pieces shown below would be placed on top of each other before pouring the lead alloy into the funnel-like shape at the top, marked c and b.

The alloy was such that a type would cool and turn solid almost instantly, allowing for quick production of identical types.

As mentioned earlier, Korea developed bronze-based types for printing, which later got adopted in China. Wouldn't that put Asia on equal footing with Europe in terms of printing?

No, because bronze is not ideal for making types. The melting temperature is twice as high, making it far less practical to use. Secondly, bronze, like most metals, shrink when cooled. That made it hard to make an accurate duplicate of your type.

The Korean method relied on creating a matrix (mould) in clay using a carved wood type. In other words, a wood type was used as punch instead of a steel type. A clay mould is naturally not very durable. Gutenberg's method involved punching an indentation into a copper plate. A copper matrix was naturally far more durable and could be used repeatedly.

from Hacker News https://ift.tt/PKMBw3T

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.