“Nolan came to me one time and he said, ‘On a TV set, when you turn the vertical hold on the TV, the picture will go up, and if you turn it the other way, it goes down. Why does it do that?’ I explained it to him. It was the difference between the sync and the picture timing. He said, ‘Could we do that with some control?’ I said, ‘Yeah, we probably can, but we’d have to do it digitally, because analog would not be linear.'” – Ted Dabney, co-creator of Computer Space and co-founder of Atari. – http://www.technologizer.com/2011/12/11/computer-space-and-the-dawn-of-the-arcade-video-game/

Fixing Computer Space

I was born in 1964, long before the first commercial video game. My dad is an electrical engineer and so his shop was always full of electrical components, soldering irons, and test equipment that we kids were encouraged to play with. One favorite of mine was his oscilloscope. It looks like this:

I didn’t really know how to use it, but I figured out how to turn it on and make it show wiggly lines on the screen. One of my favorite things to do with it was to shoot “UFOs”. I would have it show a simple dot and then move it around with the V-POS and H-POS controls until eventually getting it in the center of the crosshairs. Then I would “shoot it” by twisting the focus knob and it would blow up into a big fuzzy blob which I would then fade out by twisting the intensity knob slowly down to zero.

Little did I realize that these early fantasies played out on a glowing green screen would lead to a lifetime of work and fun in the video game business. I published my first game (“Princess and Frog”) through a company called ROMOX in 1982, the same year I graduated high school. From the mid-1990s until 2004, I built and ran Microsoft’s game publishing business and launched the original Xbox.

Over the last few years I’ve become more interested in learning about the roots of the business. The industry is filled with incredible stories about how things began. But reading stories isn’t the same as being there. What was it like for a programmer working on the Atari 2600 back in 1977? I got a sense for that a few years ago when I wrote my own game for the machine: “Halo 2600” (play it at www.halo2600.com).

The last year or two I’ve been collecting some relics from the early years for a small home arcade. I have some early consoles and games, a few pinball machines, and a Robotron, converted to play several early Williams arcade games. The more I learned about the early days the more things kept coming back to one machine.

Most people would say the modern arcade game business started with the creation of Atari and the release of Pong in 1972, but as with most things, most people are wrong. The first commercial arcade game was actually released a year earlier, in 1971, by a company most people today couldn’t name. That company was called Nutting Associates and its chief engineer at the time of the release was a crazy character named Nolan Bushnell. The same Nolan Bushnell who would soon quit to start Atari and change the world. But before that, he and his partner Ted Dabney would create and release the first commercial video arcade game, a machine called “Computer Space”.

Maybe you’ve seen the iconic advertising flyer for the game (below). Maybe you remember seeing it briefly in the movies “Soylent Green” or “Jaws”. Maybe you’re even old enough to remember playing it. However you became aware of it you have to admit one thing: It’s sexy. It screams 1970’s. It could just as easily have been a simple screen in a box, but that wouldn’t have been good enough for Nolan Bushnell.

The more I read about it, the more I knew I wanted to have one in my collection. I searched online. I watched eBay for more than one year. A red one in great shape came up for auction at one point, but the auction disappeared before I even had a chance to bid. No doubt someone had cut a private deal with the seller.

Then, one day, this machine came up for auction:

The description said:

“BAD MONITER. One or two of the tubes seems to be bad. Appears all other electrics work, as lights come on and game boots. My Family are the original owners; grandfather had an arcade back in the 60’s and 70’s.”

I knew from my research that the yellow machines were some of the first produced. They are the rarest color with less than 20 known version in existence. The price wasn’t cheap, and I’ve made enough purchases on ebay to know not to completely trust the description, but it was a yellow one and I wanted it! I pressed “buy-it-now” and soon the machine was on the back of a delivery truck, making the long, cross country trip from Florida to Seattle.

As I waited for it to arrive I had plenty of time to think, and the more I thought, the more concerned I became about whether I would have what I need to fix the monitor. From what I had read online, the game used an old General Electric black and white TV. One source said it used an SF series chassis (whatever that was), so I searched on eBay and found a working SF TV. It was relatively cheap and seemed to be the right model, so I bought it, figuring, if nothing else, that I could swap tubes and other parts out of it to fix my machine. The eBay ad looked like this:

“Really cool red white and blue GE television. Hooked up and works fine. All knobs work and antenna is not broken. Nice old TV.”

The machine arrived on December 1st with the other TV due a few days later. I proudly posted a picture on Facebook and received several hundred “likes” from friends in the industry. Then I crossed my fingers, plugged it in, and turned it on. As promised by the seller, nothing happened.

“In the early ’70s monitors were heinously expensive. The solution was to synthesize raw composite video and feed it in to a cheap off-the shelf television set.” – Retro Videogame Magazine, issue #1, page 40.

Fixing the monitor

Although nothing was showing up on the front of the screen, the vacuum tubes in the back of the TV lit up, including the picture tube. I had no idea what was wrong or how to fix it, but I was optimistic that it would just be “one or two bad tubes” as the seller had advertised.

This seemed like the perfect opportunity to get in a little father/son bonding time. My dad put himself through college working in a TV repair shop, back in the day when all TVs had tubes. I’m sure pops can help me fix this up quick!

In preparation for his visit I pulled the TV out of the cabinet so we would have easy access to it. As I had read online, it wasn’t just a picture tube like in more modern arcade games, it was a whole TV, just stuck into the cabinet. These early Computer Space machines use a TV called the GE Adventurer II. It looks like this:

Dad came over, and he brought with him a gadget I vaguely remember seeing in his shop when I was a kid. It’s a Tube Tester. You can see it in the picture below:

We pulled a tube and tried to test it, just to warm up to figuring out the problem. Unfortunately his tube tester was actually too old for the tubes in this TV! He fixed TVs in the late 50s and this TV was more than a decade newer than that. Quickly he was muttering things like “I’ve never seen a tube with this many pins”.

It turns out the Adventurer II was one of the last tube TVs manufactured. It was a hybrid of the old vacuum tube technology and the up and coming solid state components that we are more familiar with today.

Despite our failure at testing the tubes, he was able to pretty quickly point the finger at a suspicious looking tube he called the “high voltage rectifier”. Unlike the other tubes, it wasn’t lighting up when the power was on and it’s the last thing the video signal passes through before it reaches the picture tube, which is the part that everyone says can kill you.

Open any TV or monitor with a cathode ray tube (CRT) in it and you will see dire warnings about high voltage and shock hazards. Search the internet and you’ll see many more. You may also come across this more measured advice: http://lowendmac.com/2007/the-truth-about-crts-and-shock-danger/. Before I go any further I’d just like to say that I’ve worked with electricity a fair amount. I’ve done household wiring. Installed a sub-panel, sprinkler system, etc. I try to be very careful. I have been shocked when I made a mistake. It didn’t kill me (yet…). There is some danger to what I’m about to describe. It’s not as bad as some people will make it out to be. That being said, if you don’t have experience with it, please don’t use this document as an excuse to hurt yourself. Okay, ’nuff said. Back to the story…

The day after my dad left I was feeling kind of stuck. I wasn’t sure how to proceed so I decided to pull the circuit board from the TV and remove the high voltage rectifier tube. I did this carefully (see previous paragraph) and did not kill myself, but as I worked it became clear that this TV was never going to run again. The socket holding the rectifier tube crumbled in my hand when I tried to remove it. The wires fell from where they were attached. And worse, the “flyback transformer” was cracked and also fell apart when I touched it.

This dog will not hunt.

But that’s okay because, I had ordered that back up TV off of eBay, remember? And it was due to arrive any day. In fact it arrived later that afternoon and I opened it up that evening.

Bad News

Unfortunately, despite what looked like decent packaging to me, the “new” TV arrived with a broken picture tube. The very back pointy end of it had clearly hit something in shipping and snapped off. Oh, also, did I mention that I had bought a 12 inch TV and (it turns out) the game uses a 15 inch one?

So there I was, staring glumly at two TVs. A 15 inch with a possibly okay picture tube but completely rotten guts and a somewhat similar (though slightly newer) 12 inch TV with good looking guts and a definitely broken picture tube. The answer was obvious, if daunting: Could I combine the two to create a sort of FrankenTV? At first it seemed preposterous, but hadn’t I seen a forum post about a guy transplanting the flyback transformer from one TV to another to fix his Computer Space? (this post: http://atariage.com/forums/topic/129003-computer-space-monitor-repair-and-info/). That made it seem like it might just be possible. Besides that one post, the internet was silent on the subject, other than to say that my chances of finding another GE Adventurer II were slim.

In the end I decided I had nothing to lose so I gave it a go. There were about a dozen wires connecting the picture tube to the main circuit board and they were color coded. They also appeared to be the same colors connecting to the same places on the tube on each TV, so I cut all the wires on the old TV and removed the board:

Then I cut all the wires on the “new” TV and removed its circuit board. Finally I reconnected all the wires from the new board to the old CRT. I also had to solder three new wires to the correct points on the circuit board of the new TV. These wires correspond to video, audio, and ground and are used to bring the signals from Computer Space into the TV (bypassing the tuner). I used the post, mentioned above, as my guide for where to connect these wires. It turns out the author gets the ground and audio inputs switched in his description but that was easy enough to see.

Here’s a picture of the new wires coming in:

Finally I put everything back together, crossed my fingers, and plugged it in. The back looked like this:

Well at least the tubes are lighting up and no smoke is coming out. The front, however, looked like this:

Sigh. That does not look like Computer Space. Well, what was I thinking? That it would be that easy? Maybe a 12 inch board can’t drive a 15 inch tube? Maybe this newer board wouldn’t work with the older tube? Didn’t I notice that there was a resistor between two wires where they attached to the 12 inch tube, but not on the 15 inch tube? Maybe that mattered? I had a million questions but no answers.

I came back a couple times over the next few days to fiddle with it. The most promising thing I could think of was to mess with the horizontal and vertical hold knobs, but no matter how I turned them I couldn’t get anything that looked close to the field of stars I should be seeing coming from the machine. The best image I could get looked like this:

That’s definitely not Computer Space, but what did it mean? I thought that maybe I was seeing multiple images overlapping each other, a side effect of switching to a bigger tube? If only I could move the horizontal hold knob far enough maybe I could un-overlap them? But if I went in either direction from this image things just looked worse.

I sent the image to my dad. He said it looked “promising” but couldn’t advise me how to proceed. Out of desperation I sent it to my former Xbox co-worker and classic video game restorer Seamus Blackley. He didn’t know what I was seeing. I also sent it to a guy named John Robertson who works on Computer Space machines in Vancouver. He also didn’t know what to do.

I was completely stumped. Maybe combining the two TVs was a bad idea, but I didn’t have a better one. I sulked for a couple days and then came in one morning with a new theory: What if the TV is fine? What if it’s working exactly as it should be but the video signal is bad coming out of the machine? To test the theory I pushed (not so gently) one at a time on the three Computer Space game boards, and something magical happened. A new image appeared!

My god, it’s full of stars!

Hurray, my FrankenTV works! And the game works! Or does it? Shouldn’t there be saucers flying around? Why is there no sound? When I put a quarter in and start the game the counter runs really fast and the game ends almost immediately. The players ship (the rocket) appears but it looks funny and I can’t make it move. Clearly there is much more work to be done.

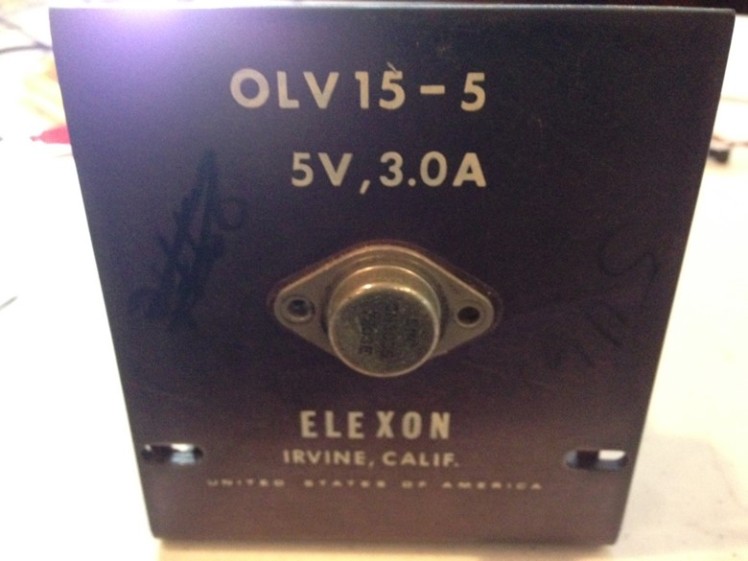

“Computer Space uses three circuit boards mounted in a rack. Only 5 volts is needed to run the boards (at 3 amps). The stock linear power supply frankly is a piece of junk and runs hot.” http://www.pinrepair.com/arcade/cspace.htm

Fixing the Power Supply Part 1

Before I tried to dive into the three very scary looking circuit boards filled with logic chips I figured I should check out the power supply. I measured the output and what was supposed to be 5 volts was slightly less than 4. “Well there’s your problem!” I thought. “This is going to be easy!” I had three options: rebuild the existing power supply, buy a new one online (“only” $750! http://www.flippers.com/catalog/product_info.php/power-supply-computer-space-p-2128), or buy a modern switching power supply. I chose option #3. I mentioned my choice to Seamus in email and his response was “Just rebuild the real supply lazy ass.” But based on the advice in the pinrepair link above I should buy a modern switching power supply, and that would definitely be easier than trying to fix the old one, so I ignored Seamus’s advice (a decision I would later regret) and drove to nearby Vetco Electronics to see if I could pick up a suitable power supply.

I feel very lucky to live near Vetco. It’s an old school electronics store, kind of like Radio Shack back in the day, but on steroids. They have long aisles filled with nothing but resistors and capacitors. They sell everything from the 7400 series logic chips I would soon need to Arduinos and 3D Printers.

I asked a friendly salesman at Vetco where I would find a switching power supply with 5 volts and at least 3 amps and he directed me upstairs to their surplus section and pointed me to a bin full of cute little supplies that were rated at 4 amps at 5 volts. They looked perfect for this application so I bought one, took it home, and installed it, bypassing the old power supply. I adjusted it to output a steady 5 volts and everything was great. You can see it mounted below the boards in this picture:

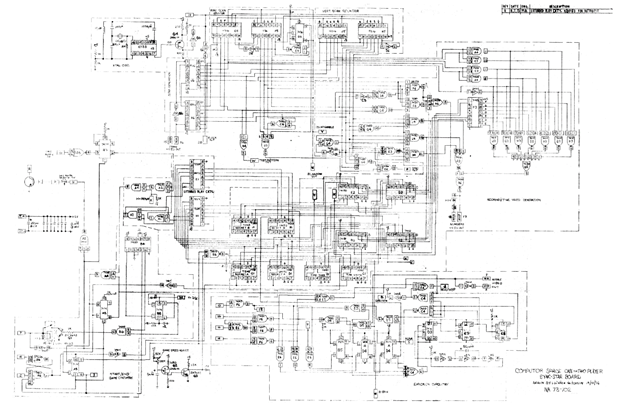

With the new power supply in place the display seemed brighter and steadier, but all of the problems I had noticed were still there. Just putting in a new supply didn’t fix the game. To do that I would have to try to understand the schematics and dive in to fixing the game boards. A daunting proposition for someone who had never done anything like that before. Here’s a picture of the schematic for one of the three game boards:

“Always aware of the importance of presentation, Bushnell put special emphasis on creating an elaborate futuristic cabinet to hold his game. He ended up sculpting a cabinet with rounded corners out of modeling clay. Page 27, “The Last Quarter” by Steven Kent.

Fixing Chips

There was a long list of obvious problems:

No enemy saucers.

Game counter runs too fast.

Thrust is broken: player’s rocket will not move.

As I worked on it more I realized that there was also a long list of subtle problems:

Rocket is missing a pixel.

Rocket thrust is missing a pixel.

Rocket Missile shoots the wrong direction from some rotations.

Rocket Missile only shoots at diagonals, not left/right or up/down.

No sound.

Where to start? I picked one of the problems at random, the lack of enemy saucers, and tried to track it down.

Fixing Saucers

Before I could begin to figure out this problem I would need the schematics. Schematics are like a road map that show how electricity flows from one chip to the next. Fortunately they are available several places online. I used these: http://www.computerspacefan.com/ComputerSpace.pdf

The game has three printed circuit boards: the memory board, the motion board, and the sync-star board. You can see the schematic for each board on pages 20-22 of the above .pdf file. Even if you are used to reading schematics I think you will see that these are complicated and messy (more on that later). If you aren’t used to reading them, like me, well, good luck.

But I refused to give up. I spent hours poring over the images, trying to make sense of what I was seeing. At some point I stumbled on this subsection of the motion board:

“Saucer Enable? Yes, I would like to enable the saucers, thank you very much.” But how to figure out if this was broken?

A few months earlier I had purchased a “Logic Probe” in case I needed it to fix a pinball machine. I never did, so it was still sitting it its package. It looks like this:

I’d never used one before, but apparently these can be handy gadgets. You connect the black wire to ground and the red wire to +5 volts, then you poke around with the pointy tip and the probe tells you whether the wire you are touching is a logical 1 or a 0. It does this by lighting a “HI” or “LO” LED and also by emitting a high or low sound. If the signal is changing quickly it flashes both lights and makes even more sound.

So… I poked around. I found chip A3 on the board and googled “7430”, the name of this logic chip. I found a picture that looks like this:

See how there’s a semicircle on the left side of the picture? The chip has that same thing on it. It shows you which way is up. Once you know that you can figure out which pin is #1, #2, etc.

I probed the input pins and they were all doing stuff that seemed reasonable but when I touched the probe to pin 8, the output pin, the logic probe was completely silent. No lights, no beeps. The signal should be either high or low, but according to the probe it was neither. “I think this chip is bad. It must be replaced!”

In theory I had the tools I would need. I own a good soldering iron with adjustable temperature control and a cheap “solder sucker” which looks like this:

All I needed to do was heat up the solder on each of the 14 pins of the chip, suck it up with my solder sucker, remove the chip, put in a socket and finally plug in a new chip. Still, I knew it wouldn’t be that simple. I had heard dire warnings about ruining printed circuit boards that basically said “if you don’t know what you are doing, don’t do it.” I didn’t know what I was doing, but I wanted to do it! So, I resorted to the modern version of an education: I watched some youtube videos. The videos were all similar. They showed happy men (always men) with a soldering iron in one hand and a solder sucker in the other. They heated up a pin, usually on something big like a resistor, put their sucker on the hot solder, and slurped it up. It looked so easy! About the only thing new I learned was that solder can get old and it was sometimes easier if you mix some new solder in with the old before slurping.

Armed with my new knowledge I drove off to Vetco Electric to buy the parts I needed. “I’d like two 7430’s please and two 14 pin sockets!” I said confidently. I was buying two because I was pretty sure I’d ruin at least one in the process. A prediction that turned out to be true. “Do we have that in stock?”, “uh, I don’t know.” “Next time check. Is that CMOS or TTL?”, “TTL? I think?”, “Here let me look… Do you want the NTE version?”, “uh, yes?”. Dubious look from clerk. Okay… well here you go…

I returned home with my new parts, anxious to get started, but, of course, it wasn’t as easy as it looked on youtube. In fact it wasn’t easy at all. After several hours of heating and mostly failed attempted slurping, the chip was still firmly stuck in place and I had learned only one thing: I suck at solder sucking.

Miraculously, we were scheduled to have dinner that night with my older brother and he happens to be an electrical engineer like my dad. I told him of my solder sucking woes and he looked at me like the idiot little brother that I am and asked a simple question: “Do you need the old chip?” “Well, no… I think it’s broken”. “Then just get out your dikes and cut off the pins [stupid]!”

At least I knew that “dikes” is shorthand for “diagonal cutters” so I didn’t have to ask another dumb question. I even own a pair of “dikes”, but when I tried to use them I found they were way too big for the job. Mine looked like this:

I couldn’t fit the clippers between the pins and the chip to cut the leads. I tried using a pair of nail scissors but they couldn’t cut the leads. Then I remembered I’d seen my wife with some small clippers she used for jewelry making. “Hey honey, can I borrow your clippers?” They weren’t perfect but they got the job done.

Once the chip was out of the way it was a pretty easy job to heat up each pin and pull it out of the hole with a pair of long nose pliers. The only problem was the holes were still clogged with solder. This time though, with the soldering iron on one side of the board and the solder sucker on the other, I was able to suck out the remaining solder and leave nice clean holes and pads to solder in the new chip.

The rest of the operation went smoothly enough. I put my new 14 pin socket into the holes where the chip had been and soldered each of its leads to the board. I put the new chip into the socket, plugged the board back into the machine and fired it up. And what do you know? Saucers!

Sketchy Schematics

“What Nolan did next however, would become a ritual for all game engineers that joined Atari in the early 70s; he dumped the schematics for Computer Space into Al [Alcorn]’s lap and said, ‘Go for it.’ Al was expected to give himself a crash course in the technology of game engineering by simply looking at these schematics. As Al soon found out, that was going to be next to impossible because, ‘He drew schematics in such a bizarre way that I couldn’t really ever understand them.'” – page 68, Atari Inc.: Business is Fun

The more I worked, the more I began to understand the schematics, but also to understand their weaknesses. Take this small section for example:

What is the chip at position E1? There are two different logic symbols shown. One means NOT (invert) the inputs and then do the AND function. One means NOT the inputs and then do the OR function. The actual chip ORs the inputs and then does a NOT as you can see below, which is logically equivalent to the first symbol above but not the second one.

I tried not to let this bother me…

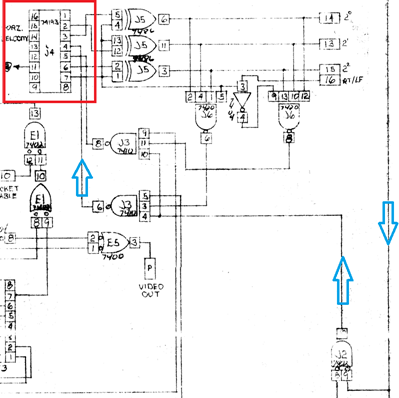

The schematic for the “sync-star” board was particularly problematic. When I first started looking at it and testing pins on my board, nothing made sense. The chip numbers didn’t even match what the schematic said. Then I noticed this note in the lower right corner:

Apparently my Computer Space has the “first model board”. So, for example:

In this image the output is not pin 12 of chip A4, it is instead pin 8 of chip A2. The schematic also contains this note:

Magic

The next thing I wanted to fix was the game timer. In Computer Space, when you start a new game, there is a counter on the screen that is supposed to slowly count up from 0 to 99. Once it reaches 99, if you have shot the saucers more times than they have shot you, you get bonus time, otherwise the game ends. Unfortunately on my Computer Space as soon as I started the game the counter would run really fast, reaching 99 in about a second and it would be game over. I started to look around to figure out what was wrong but when I came in the next morning and the counter was magically running at the right speed. I decided to move on to something else.

Thrust Part 1

At this point I thought I was ready to take on the challenge of rocket movement. The player’s rocket could rotate and fire and when I pressed the thrust button a small flame would flicker behind the rocket but it would not move. Where to start? I looked at the schematics until I found this section:

The yellow box above marks where the connection to the thrust button comes into the circuit. Once again I poked around with my logic probe until I found something that didn’t seem right. Pretty quickly I figured out that, just like the last bad chip, there was no output from one of the gates in the chip marked F3 above.

So, it was back to Vetco. This time I bought a nice small pair of dikes specifically designed for clipping leads in tight places along with the new chip and socket I needed. My new cutters look like this:

Replacing the first chip took me over three hours. This time I had the job done in about an hour. I was getting better.

Replacing the first chip took me over three hours. This time I had the job done in about an hour. I was getting better.

With high hopes I started up the game, expecting to now be able to thrust, but, as I was learning, Computer Space can be a harsh mistress. The chip WAS bad and it DID fix a problem, but not the one I was expecting. With the new chip in, the flame shooting out behind the ship was now made of two flickering pixels instead of one. That’s what I had fixed.

We don’t need no stinking ROMs

I spent more time investigating why my ship wasn’t thrusting but I wasn’t making much progress for reasons I’ll explain later, but in the mean time I kept noticing other problems. The most obvious was that one of the pixels was missing from near the bottom of the ship.

The way Nolan Bushnell implemented the ship rotations is one of the most famous things about this machine. In fact, when I posted a picture of my Computer Space on Facebook, one of the first things someone asked for was a picture of this part of one of the circuit boards. It looks like this:

See the saucer on the left and the four rotations of the rocket? In schematic form it looks like this:

These days if you wanted to hard code the shape of a graphic item in pixels you would use a ROM or Read Only Memory, but they were quite expensive in 1971 and difficult to order in small quantities. Instead, Nolan hard coded the shapes of his ships in diodes right on the board. He didn’t need to make them look on the board like they do on the screen but he did and that’s one thing that’s great about it. It also makes it super easy to debug. I just moved my logic probe down the pins of the chip outlined in green and once again found a pin with no signal on it.

Back to Vetco right? Sure, but first I was expecting a special deliver from the friendly man from Amazon.

Super Sucker

Although my solder sucking skills no longer sucked, they certainly weren’t great, and this time the chip I needed to replace had 24 pins, not 14 like the last two. Fortunately I had been reading the latest issue of Retro Magazine and it mentioned a solder sucking tool called the Hakko FR-300. Sure, it wasn’t cheap, but it was becoming increasingly clear that I had a lot of solder sucking in my future and this tool promised to make that a breeze. The Hakko FR-300 combines a soldering iron and a vacuum pump into one simple unit. It looks like this:

Mine arrived soon enough and I eagerly tore open the package and plugged it in. As I did I noticed an unsettling rattling noise from inside my new toy. Was that the sound of a loose screw in there? Ah, never mind, let’s try this puppy out! I set it to an appropriate temperature and let it heat up, which it did in a matter of seconds. I placed it on a pin I wanted to de-solder and the old solder melted immediately. I pressed the vacuum button and the pump whirred into life, instantly sucking away all the solder, leaving me with a beautiful clean pin. It was amazing! It was incredible! My life would be so much better with this new toy!

But when I tried to use it on a second pin, instead of making that beautiful sucking sound, it just hummed, somewhat violently. It sucked no solder. This sucks. The instructions have elaborate warnings about keeping the intake nozzle clean. Had it clogged already? I used the included tools to clean the nozzle, but it still just hummed. Finally I remembered that rattling sound. Had something jammed the pump motor?

Now I know most people send stuff back to Amazon when it doesn’t work, but I’m a fix it kind of guy and I really wanted this new toy to work, so I unplugged it, let it cool down, and started to disassemble it. I’m sure that voided my warranty and yada yada but if I expect to be able to fix a Computer Space, I should be able to fix a Hakko FR-300 too right? Right! So I took it apart. Inside it looked like this inside:

And what did I find? These two big pieces of plastic jamming the motor!

I took them out, put it back together, and it has been my bestest companion ever since. PS here’s a picture of the new 24 pin chip in, fixing my missing pixel from the rocket:

There is no magic

Remember how the game timer magically started working? Well, those of you who make stuff, or write code will probably not be surprised to hear that things that magically start working usually magically stop as well. We went away over winter break for a week. The Computer Space was sitting undisturbed in a locked, climate controlled room, yet when we returned the timer was broken again. Seamus suggested I look for a bad capacitor but I didn’t see anything suspicious (more on that later). I tested one of the transistors using instructions I found online and decided it was bad, so off to Vetco to get a replacement. The replacement made no difference. So I tested the other transistor and that one definitely acted funny, so off to Vetco again. This time, instead of costing about a dollar, they wanted almost ten dollars for the little transistor? What was so special about this one I wondered?

A little about transistors

As will become apparent, I have only a basic knowledge of transistors. Like most programmers, I think of them as little switches. I know they have three wires which roughly translate to the input (collector), the part that turns them on or off (base) and the output (emitter). Until I started working on this project, I only knew about two types: NPN and PNP transistors. They look like this in a schematic:

But the image in the schematic looked like the arrow was coming in from the top. It looked like this:

What the hell is that? Two bases? No collector, just an emitter? I looked up the part number (2n2646) and found out it’s called a unijunction transistor. I have no idea how it works but when I looked it up I saw oscillator circuits exactly like the one in Computer Space. At this point, a smart person would realize that a transistor they don’t recognize probably couldn’t be tested using the same method that works for NPN and PNP transistors, but I am not that person. Instead I coughed up the 10 bucks and put a new one in. And, as you might have guessed by now, it made absolutely no difference.

At this point I really wanted to work on something else, but it was hard to test stuff in the game when the timer was running so fast that the game ended in a matter of seconds. So, I put in a temporary kludge. See the part marked in red above? That’s the symbol for a potentiometer, or pot for short. A pot is a variable resistor. By turning a knob you can adjust the resistance from 0 up to the maximum value (in the case above 100K ohms). I knew that pot was there to let the operator adjust the game time. “What if I put in a bigger pot? I’ve got a 500K pot sitting right here…” and so I did. By adjusting the new pot up to close to 500K I got a game time of close to a minute which was more than acceptable for me to move on with my other fixes.

Thrust Part 2

The biggest problem with the game at this point was that the player’s ship (called the rocket) wouldn’t move. I told you above that I had fixed one problem, but all that did was make the flame bigger behind the rocket. It still didn’t move. So I started to look a little farther downstream in the schematic, but I was quickly confused by what I was seeing:

I vaguely understood that the part I’ve highlighted above in green is an oscillator. Take three not gates made out of redstone torches in Minecraft and you’ll see how it works. So that meant that coming out of the green box above would be a series of high,low (1,0) pulses. Call it a square wave. But then the pulses branch off in the blue box. One set goes straight into the red box and the other goes through a NOT gate before coming into the red box. Okay, so we have one wire going 1,0,1,0 and the other going 0,1,0,1. Then they go into a NAND gate. The AND part will only be true if it has two 1s coming in at the same time. But that would never happen, right? So the output of the red box should always be high.

At this point I’ve divided the readers into three groups: Those who have no idea what I just said and are completely confused. I apologize to this group but encourage them to continue. The second group more or less understands what I just said and is just as confused as I was. The third group understands both what I just said and ALSO why it is wrong. I’ll catch up to you in a few paragraphs. Feel free to skip ahead if you want.

I tried to verify what was going on with my logic probe but that just confused me even more. As I had expected, the output of the red box was high on my logic probe. After running through the NOT gate in the yellow box it was low (makes sense), but now my probe said it was pulsing. How could it be high and not pulsing but now low and pulsing? The rest of the yellow box was another NAND gate whose job appeared to be to let those pulses through when the thrust button was pressed. My logic probe said that it was always high (and not pulsing), whether the thrust button was pressed or not.

It seemed like something was broken, but what? To make matters worse, I had already replaced the F3 chip (in “Thrust Part 1”) so I knew that most of the parts of this circuit were okay. After banging my head on the wall for a few days I sent my brother a desperate email explaining the situation.

My brother gave me a call and explained (Duh) that the signal passing through NOT gate in the blue box would be delayed slightly from the signal that passed straight through. When they both arrived at the NOT gate, slightly out of phase, the output should make a quick pulse. He said he was “suspicious of the pulse width” and passed my email on to someone even wiser than him in the ways of such things. The second guru said “Odd looking thing. I’ll bet its working and you can’t catch it on the probe”. Both of them encouraged me to buy an oscilloscope and pointed out that USB versions that use a laptop for display are really good these days and quite affordable.

The next day I bit the bullet and ordered the Hantek 6022BE from Amazon. It looks like this:

As with most Amazon purchases though, about 30 minutes after I ordered it, I realized I didn’t need it. At least not to solve this problem. Once I understood that there were (probably) pulses on the line but that they were just too quick for my probe to see, I looked farther down the schematic in search of another bad chip.

I followed the intended path of the pulses along the path you can see marked by blue arrows below:

Assuming the right conditions were met at the few gates they passed through along the way, the pulses should arrive at the chip marked in red, 74193. I looked that number up and found out it is a counter, but it wasn’t counting! Maybe this is the problem…

So, you know the drill: another trip to Vetco, desoldering, resoldering, plug in the new chip AND… the counter counts but the rocket still doesn’t move! Sigh…

If you don’t know what’s wrong, fix something else

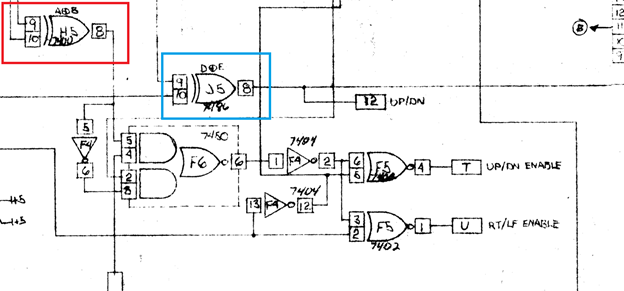

At this point I decided to take a break from the Thrust problem and look at some of the other problems I knew about. Who knows, maybe fixing them would somehow fix thrust. The first problem was that the rocket would shoot at the correct angles when facing some directions but not others. I focused on the part of the schematic that dealt with rotation and poked around with my logic probe. Again I found a chip (H5 marked in red above) with a pin that didn’t register on the probe.

Replacing the chip fixed the problem, but as I tested it I realized I could only shoot at 45 degree angles. Is that really how Computer Space was supposed to work? I watched several Computer Space videos online until I found one where the player clearly shoots horizontally. There must be yet another problem.

Again I focused on the rotation area and soon found yet another bad chip (J5 marked in blue). Replacing that chip made it so I could now correctly rotate and shoot in all directions. Man, I was getting good! But I still couldn’t thrust. What was up with that?

Thrust, the final chapter

My original list of problems had been narrowed down to just two: There was no audio and the rocket still wouldn’t move. I knew the audio problem was likely to be tough for me because it was not just electronics, but analog electronics, so I had no choice but to keep working on thrust until I fixed the problem.

I was convinced that I had fixed all the problems on the memory board. For example if I rotated the rocket to the right and held down the thrust button I could see the horizontal velocity count up until it was at the maximum value and put that value correctly to the pins 13-16 on the memory board as shown above. But if the memory board is all working now, that means the problem is on one of the other two boards. Probably the motion board, since its job is, you know, motion.

There was just one big problem. The boards are stacked on top of each other, like this:

Earlier, when I fixed the no saucer problem, I just removed the memory board and poked around on the motion board. Without the memory board the saucers (and the rocket) wouldn’t draw on the screen, but the saucer movement stuff was still working so I could debug it. In this case though I knew the thrust wouldn’t work without the horizontal and vertical velocity values generated on the memory board, but I couldn’t get to the motion board with the memory board in place!

Earlier, when I fixed the no saucer problem, I just removed the memory board and poked around on the motion board. Without the memory board the saucers (and the rocket) wouldn’t draw on the screen, but the saucer movement stuff was still working so I could debug it. In this case though I knew the thrust wouldn’t work without the horizontal and vertical velocity values generated on the memory board, but I couldn’t get to the motion board with the memory board in place!

After puzzling over this predicament for a bit, an idea presented itself: What if I unbolt the connector for the memory board and, sort of, tip it forward and then plug the memory board back into it? I messed with the rusty bolts holding the connector for a few minutes until I was able to get it unhooked. When I plugged the memory board back into the connector it hung down like this:

That gave me access to the motion board while still having the memory board in place and I was ready to attempt to figure out once and for all why the rocket wouldn’t move.

Thrust – flip flopping

The motion schematic felt cleaner, for some reason, than the memory schematic. It had four long rows of chips that, after some staring, I realized are responsible for each of the four objects in the game (saucers, saucer missile, rocket, rocket missile).

I could see where the horizontal and vertical velocity for the rocket came into the schematic, that part is clearly labeled, but what was supposed to happen next?

The output of chips F2 and F5 weren’t changing at all. Why was that? The velocities were okay, but each one was ANDed with the output of C1 and D1 at the bottom and what are those? Flip Flops. A flip flop is like a one bit memory cell (at least to this programmer…) It’s either on or off. I looked up how these are wired and the datasheet for the 7476 chip said that if the input on pin 1 was changing then the flip flop should toggle (or flip). I put the logic probe on pin 1 of chip C1 and boy was it changing. The high low and pulse lights were all flashing like crazy, but when I put the probe on the output (pin 15), I just saw a steady low signal. The flip flop was not flipping! And so it was time for another trip to Vetco, but this time they didn’t have the chip that I needed. Disaster! I ended up having to order it online and wait almost a week to find out if I had made the correct diagnosis.

Victory!

The new flip flop arrived and I installed it. I started the game and tentatively pressed on the thrust button… The ship moved! I could fly around the screen at last!

“Ted had designed additional circuitry, at Nolan’s request, to create a noise that sounded like an explosion, and more circuits to trigger the sound and other game mechanics at the right time.” – Page 40, Atari Inc. Business is Fun.

Audio Woes

Fixing thrust was a bitter sweet moment. It was sweet because I had been working on it for so long and finally got to the root cause of the problem. But I felt a strange twinge of sadness as well because I could, for the first time, see the end of the project approaching on the horizon. The game was now working 100%. The only problem left was to fix the sound. The audio circuitry occupies the upper right corner of the memory board so it’s easily accessible. It looks like this on the board:

And I even had the schematic:

And I even had the schematic:

How hard could this be?

Audio First Steps

Before I got too far, I wanted to make sure the TV audio was working and the game audio wasn’t. If you remember from earlier, the instructions I had followed to connect audio into the SF chassis were pretty sketchy in the sense that the description clearly had the audio wire and the ground wire swapped. I decided to test the TV audio by hooking up the audio output of a Nintendo Entertainment System (NES) to the TV audio hookup. I popped in a Tetris cartridge and hit start while I held the audio and ground wires to the audio output of the console. It didn’t sound great but I could clearly make out the familiar Tetris song, so I assumed the TV audio was okay.

Next I tried hooking the game audio to the TV but I heard nothing but noise.

Op Amps

We were getting ready to head out of town for a few days so I was a little rushed. I just poked around a bit with my multi-meter comparing voltages to shown on the schematic but nothing seemed right. The 12 volt supply voltage was okay but beyond that nothing made sense. For example the schematic says the output voltage should be 3 volts ac, or 12 volts for an explosion, but I was measuring less than half that:

Since the output at that point comes from the only integrated circuit in the entire sound system I (probably wrongly) decided that it must be to blame. I looked up the number N5741A and found out it’s something called an Op Amp, short for operational amplifier. Its job is to make things louder, I understand that. I looked up the part and supposedly Vetco had it in stock but when I arrived they couldn’t find it. They had a smaller 8 pin version but they said the pins weren’t compatible with the 14 pin version I needed. So once again I had to order online and wait the better part of a week for the chip to arrive.

The sound of silence

While waiting for the op amp I looked for something else to work on. When the game isn’t running it’s supposed to be quiet, but it wasn’t quiet at all. It sounded kind of like that noise you hear when you put a big seashell up to your ear. It sounded like the ocean. The full schematic for the game audio seemed intimidatingly complex to me at this point, but maybe I could fix one small thing at a time. Why was it noisy when it should be quiet?

Just before the audio signal was to go out to the TV it passed by a transistor connected to a wire called “Audio Gate (+ = off)”. I figured out where that was on the board and put the logic probe on the audio gate wire. Sure enough it was high when the game was off and low when it was on. So when the game is off the transistor Q12 should be on and shorting the audio signal to ground which should make it quiet. But it wasn’t quiet.

Maybe transistor Q12 was bad? I had an appropriate replacement from an earlier run to Vetco so I popped it in. No luck. It sounded just as bad as noisy as before. I puzzled over this for a bit before deciding to check the audio gate signal with that oscilloscope I had purchased earlier but barely used. Maybe more was going on than I could detect with the logic probe?

Sure enough the signal that looked solidly high or low on the logic probe looked like a mess on the oscilloscope. I figured that noise was rapidly opening and closing the transistor when it should be solidly open and that was why I was hearing noise on the output. But where was the noise coming from? The audio gate signal was coming directly from the third board in the stack, the Sync-Star board, so I pulled the first two boards out and ran with just that board. I poked around trying to figure out what was going on, but everywhere I looked I saw noise. What appeared to be clean digital signals on the logic probe were a mess on the oscilloscope. But where was all that noise coming from?

Timer Part 2

While trying to figure out why the signal into Q12 was so noisy, I found myself looking at the Sync-Star board. The only way I know to get rid of high frequency noise is with capacitors so I was staring at the capacitors and one looked very suspicious, like the pictures of bad electrolytic capacitors I’d seen online. It clearly connected into the timer circuit. How did I miss this before? It’s outlined in blue below:

I yanked it out and hooked it up to my capacitor meter. It read almost 0 when it was supposed to be 5 microfarads. No wonder my timer was running too fast. I put a new 5mfd cap in and put back the original 100K pot (removing the 500k one I had kludged in earlier) and the timer started working exactly like it should. I had finally fixed the real problem with the timer and it was exactly what Seamus had told me it would be.

Op Amp Part 2

Meanwhile my new op amp arrived and I eagerly desoldered the old one, soldered in a new socket and popped in the new chip. It looked like this:

But nothing changed. I got the exact same readings I had with the old chip. Maybe fixing the sound wasn’t going to be so easy after all?

But nothing changed. I got the exact same readings I had with the old chip. Maybe fixing the sound wasn’t going to be so easy after all?

Simplify

At this point I really wasn’t sure what to do. If the op amp wasn’t bad, what was? And how would I find it among the complicated maze of resistors, capacitors and transistors? I stared at the schematic in dismay until finally I noticed something. It looked like the op amp had two inputs. Sure enough, when I googled “op amp” I found images like this:

So the op amp has a “non-inverting” or + input and an inverting or – input. Now looking at the whole schematic I could see that most of it fed into the non-inverting input (outlined in red below), but a relatively small and simple section (outlined in green) fed into the inverting input.

Maybe I could temporarily disable the big red section and just get the little green section (that is clearly marked on the schematic as “missile sounds” and “turn sounds”) working and then tackle the much bigger and more complicated part? But could I run an op amp only with only the inverting input? Again, the internet said, “sure, why not?” with images like this:

That looks almost exactly the circuit I’m dealing with and seems to say that as long as I connect the + side of the op amp to ground I can send my signal in the “-” side and it should work just fine.

So I unsoldered one end of the capacitor that connected the entire “red” section and also a resistor and then shorted the + pin on the op amp to ground so that I only had the small green section feeding into the amp AND… nothing happened. I still didn’t hear any sound at all.

False Optimism

“Okay, so maybe that’s good”, I thought. “If it doesn’t work with just the green section then the red section might be fine. Maybe I’ve narrowed the problem down to this little green section and it’s so small that it’s going to be simple to debug. There just aren’t that many things going on here. Either the input signals are bad, or one of the resistors is bad (unlikely) or a wire trace is broken on the circuit board, or there’s a short, or some such. It should be obvious in no time.” And so I set out to track the problem down.

A Long Project

At this point in the story I should note that I had been working on this (part time) for a month and a half. When I say stuff like “and then I thought”… what that really means is I tried ten other stupid things, sometimes over several days, until I finally had a decent thought about how to move forward. With that note, I return to the story…

Testing Testing

I measured the resistors. They all matched the values shown on the schematic. I measured capacitor, it was fine. I made sure the traces were okay and that I had continuity between all the points that should be connected. Everything looked perfectly fine.

I got out the oscilloscope and watched the signals coming in for missile sounds. They looked good. I watched the signal for turn sounds. Turning one direction made a nice even square wave but turning the other direction the square wave looked much more feeble. All the signals were noisy.

If I pulled out the op amp the signal looked okay. If I put in the op amp the signal went away as if it had been overpowered in some way.

I spent days like this. Testing and retesting. Seeing a few strange things: the noise, the funny square wave, but none of it made any sense.

Desperation

Once I had checked and rechecked everything several times, I was back where I started, wondering about the op amp. Maybe the new one was bad too? I looked up the pin outs on the 8 pin version of the op amp, the one they had at Vetco that the guy behind the counter said wouldn’t work and I realized that it would work. I just had to put it in the right place in the socket to line up the pins with the 14 pin version. And so, I made the drive to Vetco once again and bought two of their 8 pin op amps. When I got home I pulled the 14 pin op amp out of the socket, plugged the 8 pin version in in the right place AND… still no sound.

Recapping

Whenever I was completely out of ideas I would replace a few of the electrolytic capacitors in the part of the audio section I had disabled. These capacitors are infamous for going bad over time so it wouldn’t hurt for me to replace them with fresh ones (as long as I got the polarity of their leads correct when I put the new ones in). I always tested them as I took them out and although they were always out of spec they were never wildly off, at least not yet…

A Lucky Guess

Frustrated by my slow progress on the audio, I decided to look into something fishy I had noticed earlier: When I pushed one of the rotate buttons I got a nice square wave feeding into the sound circuit, but when I pushed the other one the square wave was incredibly noisy. Where was the noise coming from? I tracked it back to right where the buttons on the control panel come in to the memory board. The two buttons come in at the places I marked red and green below:

If I put my meter on the red contact I would get (about) 0 volts and if I pushed the button I would get 5 volts. Great. But If I did the same thing on the green button, instead of 5 volts I would get about 1.8. Why so low? I suspected another chip was bad. Not bad enough to stop working since the rocket was rotating fine in both directions when I played the game, but enough to create the noise problem I was hunting. But which chip is bad, E5 or E6? If I had taken a minute to think about it I would have seen that it was probably E5 because both buttons connect to E6 and one of the buttons is working fine. Instead I just looked at the bad button and said to myself, “well it’s connected to two chips, either of which could be bad. One is a 7402, which I don’t have sitting here on my desk, and one is a 7400 which I happen to have right here…” So I yanked the 7400 (E5) and put in a new one and the problem was solved.

Still Stuck

But even with my square waves looking the same while turning both directions, the sound still didn’t work. I didn’t expect this to fix the sound after all, just to make the signal look the same. So that was one mystery solved but the other mystery was still out there: why were all my signals so noisy? When the rotate signal came into the “green” section of the audio chips, it immediately went through a 47K ohm resistor. That caused the voltage to drop greatly which made the signal much smaller relative to the noise I was seeing. Maybe there was more noise than signal and that’s why I didn’t hear anything recognizable?

Sweet Dreams

Sometimes when I’m stuck on a hard problem I think about it at night before I go to sleep, and sometimes I dream about the problem, and sometimes those dreams are actually helpful. I had dreamt about the audio several times, more like nightmares really, and so far it hadn’t been any help in tracking down the problems I had been having, but one morning I woke up with a clear thought in my head: The Power Supply. I had installed that new switching power supply at the beginning of the project. Could that be the source of all the noise? I hadn’t seriously considered that before because, well, that part was new and new stuff is always better right?

Sure enough when I put the oscilloscope directly across the power supply I saw the same noise I was seeing throughout the game. I disconnected the switching supply and reconnected the old bad power supply. It wasn’t strong enough to drive the display properly but it was much less noisy. I should have taken Seamus’s original advice and rebuilt the old power supply.

Power Supply Part 2

So I took the old supply off the machine and started to take it apart. It was in pretty bad shape. The transformer was completely rusty and something was oozing out of the end of the big 10,000mfd capacitor. It looked like this:

I started to disassemble it with the intent to replace all the obviously bad parts. I had a schematic for it but it didn’t have a lot of details, for example, what transformer do I need to replace the rusty one? I tried searching online for the name of the power supply, OLV15-5, and something funny happened: Google came up with some ebay links that looked very much like what I was looking for. The manufacturer name was Elpac, not Elexon, but other than that they looked virtually identical. Even better, there was one for sale that was apparently unused, in the original packaging, for only $40. I ordered it immediately and about a week later it arrived. It looks like this:

Here’s a picture of the other side of the old and the new supplies (the old one is disassembled):

I put the new supply in and it worked great right out of the box. I no longer had random noise throughout the system. The signal through transistor Q12 was nice and quiet which made the game quiet when it wasn’t running BUT… when the game was running there was still just noise, no game sounds.

Running Out Of Time!

On Monday, I realized that I was out of time. I had worked on this project since the beginning of December and it was now February 9th. We were leaving on Sunday for a week long vacation and when we returned I was hosting three days of meetings in the same room I had been working out of, so I had to have everything cleaned up and put away by Friday. I had to get the audio working this week but I had no idea how I was going to do it. I decided on a crazy plan: The idea of getting just a small part of the audio working first had been a complete failure so what if I took the opposite approach? I would finish replacing all the electrolytic capacitors, and then hook it all back up and see what happens.

I was already more than halfway through the caps so it didn’t take long, maybe an hour, for me to complete the task. As I replaced the final capacitors I discovered one that was completely bad, just like the one that I had eventually replaced to fix the timer circuit. Here it is reading zero on my meter:

Once the caps were replaced I soldered back in the capacitor and resistor I had removed to isolate the “red” part of the audio section that fed into the non-inverting part of the op amp and fired everything up and I heard… nothing but noise.

Whit’s End

“Arrgh!!” I had been at this for weeks and it still didn’t work! What the heck was going on? For the nth time I hooked the oscilloscope up to the audio output and I saw nothing interesting on the scope. With nothing better to try I left the scope connected to the audio out from the game but disconnected it from the TV. “What’s this?” All of a sudden I was seeing a pattern on the scope that looked like an audio signal. It looked like this:

I was excited but I wasn’t ready to believe what I was seeing. I needed to hear it to know if it was true. I pulled out a set of iPhone headphones and carefully laid the audio wire and ground on to the correct parts of the plug and there it was… The beautiful sounds of Computer Space. It sounded like this:

I was excited but I wasn’t ready to believe what I was seeing. I needed to hear it to know if it was true. I pulled out a set of iPhone headphones and carefully laid the audio wire and ground on to the correct parts of the plug and there it was… The beautiful sounds of Computer Space. It sounded like this:

https://www.youtube.com/watch?v=o019DYaSxUQ

It didn’t just sound good, it sounded perfect. The rotation sound was there. The missile sound was there. The thrust sound was there and when a ship blew up the deep rumbling boom was there just as it should be.

WTF?

So what was up? How broken was sound to begin with and how much was a problem with the TV I had built at the beginning of this story? I simply don’t know. Maybe some Computer Space expert will read this and let me know what I did wrong. All I know is that I followed somewhat sketchy instructions from the internet on how to connect the game to a GE SF chassis, that those instructions were clearly wrong at one point, mislabeling the audio input and ground wire. That I had tested that I could send an audio signal into the TV and hear it when I hooked it up to my NES, but that it doesn’t work with the audio signal from my Computer Space.

I pulled the board from the TV and verified that I had soldered to the right points. I compared it to the images on the internet. Then I pulled the old rusty board I had saved from the original TV. It’s a little different (S3 chassis) but I noticed that in addition to the wires being connected to it for audio, ground, and video, it looked like there was a resistor added between the audio input and ground. Could that have something to do with it? Maybe I didn’t cut enough wires from the tuner to the main board and an audio signal from the tuner was overpowering the signal from the game? I had many theories but no time to find out if any were true.

A Final Kludge

But I knew I had a good audio signal coming from the game as long as I didn’t connect it to the TV and all I needed was to amplify that signal and send it to the speaker on the back of the cabinet. That was a clear and easy thing to do, as long as you don’t mind sacrificing a small amount of authenticity. At this point I didn’t have time to be picky.

I drove to Vetco and purchased a simple 1 watt amplifier kit. The kind they use to teach kids how to solder. It had a small chip and a few discrete components. It took me less than 30 minutes to solder together. Then I hooked two wires to the power supply, two wires to the audio output and ground, and a final two wires to the speaker and I was done. It sounded great. I finally had working audio for the game.

Cleanup

My project at this point had spread out across a large folding table and both sides of a ping pong table. I had chips, tools, schematics and new and used parts scattered everywhere. I took a final picture of all the parts I had replaced from the machine over the last two+ months before cleaning everything up:

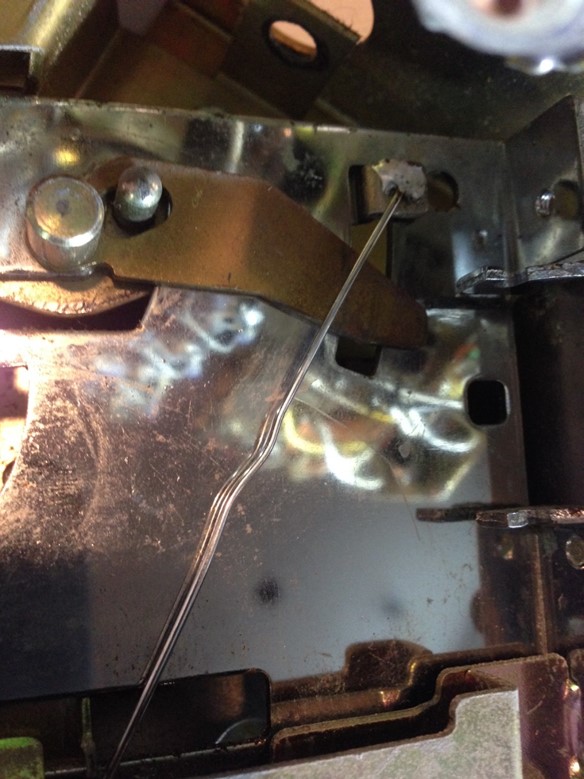

I reassembled the control panel with new carriage bolts and new old stock light bulbs I had found on ebay. I wanted to be able to play the game without putting in a quarter but wasn’t sure how to do it while maintaining the original look of the game. I decided to solder a paperclip to the coin return button in the coin mechanism. The other end of the paperclip trips the micro-switch that a quarter would trip when dropped into the machine. It works pretty slick:

I also disassembled, cleaned and reassembled the previously jammed coin counter that keeps track of how many total games have been played:

Here’s the final, reassembled and fully working machine:

Here’s the final, reassembled and fully working machine:

More To Do

Because of my rush to finish, I didn’t get to work on the physical restoration of the yellow cabinet. It needs to be cleaned and polished to return to its former glory, but that will have to wait for another day. I’m also not happy with the buttons on the control panel. One of them sticks a bit which can leave your ship spinning out of control. I really need some replacement button caps, but those are hard to come by for this machine.

“Yeah, yeah, no it’s … it absolutely … the guy is brilliant! He’s absolutely brilliant! He just happens to not be a particularly good engineer. But his imagination and his ideas and … I mean, all the ideas that came around were his ideas.” – Ted Dabney, Retro Gaming Roundup

Reflecting

I learned so much working on this project over almost three months. At the beginning I had never tried to debug a complex digital or analog circuit. I had never desoldered and replaced a chip. I had never used an oscilloscope. Now I feel marginally competent with all of those skills. In some sense I was lucky I was working on such a relatively simple machine. What if there had been a CPU running a program across a data bus? I’d need completely different tools (maybe a logic analyzer?) and I’d have to learn different skills. Maybe that’s next? Who knows.

And what of Nolan?

Until I started this project I had always thought of Nolan Bushnell as kind of a merry huckster. Part Steve Jobs and part PT Barnum. That feeling was reinforced when I met him for the first time at a PR event for a game we were releasing from Microsoft in 2000 called “Starlancer.” Our people had arranged for him to play in a multiplayer space battle with me and game designer Chris Roberts (of Wing Commander fame). We met him and shook his hand back stage, a few minutes before we were to start the event. I told him what an honor it was to meet him. His response, no doubt meant to impress, was to immediately launch into a bawdy story about a romantic liaison between himself and a waitress in the ball pit of Chuck E. Cheese. This was the founder of the modern videogame business?

But on this project I got to see another side of Nolan: the engineer. Sure he has taken credit for more than he should, including patenting Ted Dabney’s work without crediting him, but he also, more than anyone, created this game and made it fun. He solved difficult technical challenges including how to rotate a sprite on the screen and how to make a simple AI for the enemy saucers.

For all his well-documented flaws, this project really increased my respect for Nolan Bushnell and taught me about Ted Dabney’s important role as well. I learned new engineering skills, but I also learned even more about the history of the business I’ve been involved in now for almost 35 years and the people who made it great.

An Unexpected Call

Sunday morning we had the car packed and the kids loaded up for our ski vacation. I set the alarm, locked the front door and as I walked to the car my phone rang. It was my dad. I told him about my ultimate hack to fix the audio problems. He said he thought that was a good solution. He said that maybe the audio circuit wasn’t strong enough to drive the TV amplifier or maybe there was an impedance problem (whatever that means…). Then he told me the reason he called was he wanted his Tube Tester back. He needed it because my work on the Computer Space had made him want to get his old oscilloscope working again and he suspected one of the tubes was bad. I set the tester out for him on the front step and drove away, happy that, for once, I had inspired him, rather than the other way around.

from Hacker News https://ift.tt/2oGnwnV

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.